Factory Performance Tracking System (FPTS)

- Home

- Factory Performance Tracking System (FPTS)

Manage your factory overall

performance

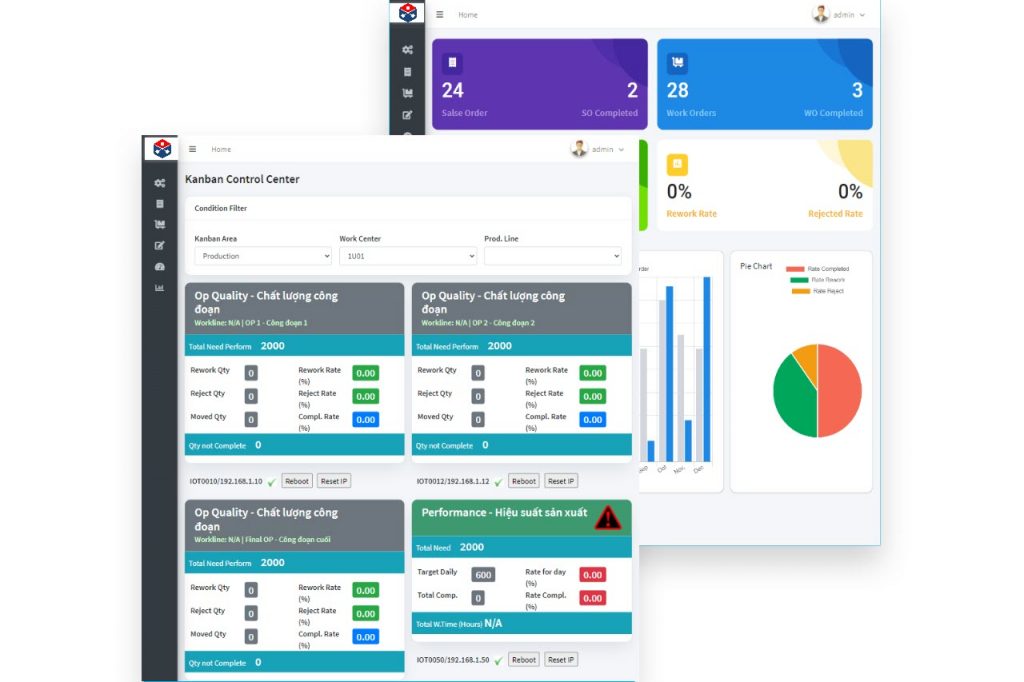

As a productivity monitoring system, the performance of the factory (or production line). The system is divided into 3 main areas of use:

+ Record and display (Worker, workshop)

+ System administration (IT, admin)

+ Monitor and view reports remotely (Leadership)

Store and display the actual recorded production result data through specialized devices (handheld, RFID …)

Help management or board of directors have a visual and realistic view of productivity and performance in the workshop

Support leaders to make the right and timely decisions

Be more proactive in orientation and next planning

Improve production efficiency, raise business level

+ Record and display (Worker, workshop)

+ System administration (IT, admin)

+ Monitor and view reports remotely (Leadership)

Store and display the actual recorded production result data through specialized devices (handheld, RFID …)

Help management or board of directors have a visual and realistic view of productivity and performance in the workshop

Support leaders to make the right and timely decisions

Be more proactive in orientation and next planning

Improve production efficiency, raise business level

Benefit Of System

- Track and record the number of each stage (Number of passes, number of rejects, number of rework). The system automatically calculates the percentage of each parameter.

- Track finished product goals for the day (Target for day)

- Keep track of total need production

- Track the number of finished products at each stage and move on to the next stage (Moved Qty)

- Track the number of products that need to be produced at each stage (Qty not complete)

- Monitor productivity and performance of each production line

- The system automatically evaluates the performance of each production line and factory

- Real-time data recording by specialized equipment Handheld Barcode / QRcode / RFID

- Each stage can be integrated and viewed directly on the LCD screen located at each stage or production line

- Help the manager or board of directors to have visual and practical information at the factory

- The interface is easy to use, easy to interact with and supports a lot of KPI Dashboards with intuitive graphs

- Web portal system works well on PC/Laptop/Tablet/Mobile